Entry into the Digital Factory

smartOEE enables a fast and cost-effective entry into the digital factory. Your production data is collected digitally and can be evaluated directly in the cloud. By automatically calculating the Overall Equipment Effectiveness (OEE), you derive optimization measures and increase the productivity of your production.

Your Benefit: Plug & Play to Success

smartOEE is a 3-month project in which we work together to uncover the potential of your machine, initiate optimizations, and sustainably increase productivity. For this purpose, we provide you with a plug & play system consisting of high-performance software and reliable hardware. We support you during commissioning and train you to ensure optimal use.

We offer smartOEE as Software as a Service (SaaS), a cloud-based software model that is available on demand and continuously enhanced with new features.

Click here to go directly to the pricing.

By using the cloud, your data is available anytime and anywhere and can be used at any time. The Edge component guarantees reliability. (Always On)

Maximum flexibility with full performance: The up time of the rental is individually tailored to your needs and you benefit from short delivery times and reliable advice.

In addition to the software, you also receive the corresponding hardware and advice from our experts. We are your partner for the entire project.

With smartOEE, you can record precise production data. This ensures transparency and enables you to calculate key production figures such as OEE and optimize your production.

After receiving the system and the corresponding hardware, you can use smartOEE immediately (plug & play). We will activate the system for you via remote access.

You can integrate your entire machine park into the system and continuously add further functions. Our commitment to continuous further development means investment security for you.

Your Functions at a Glance

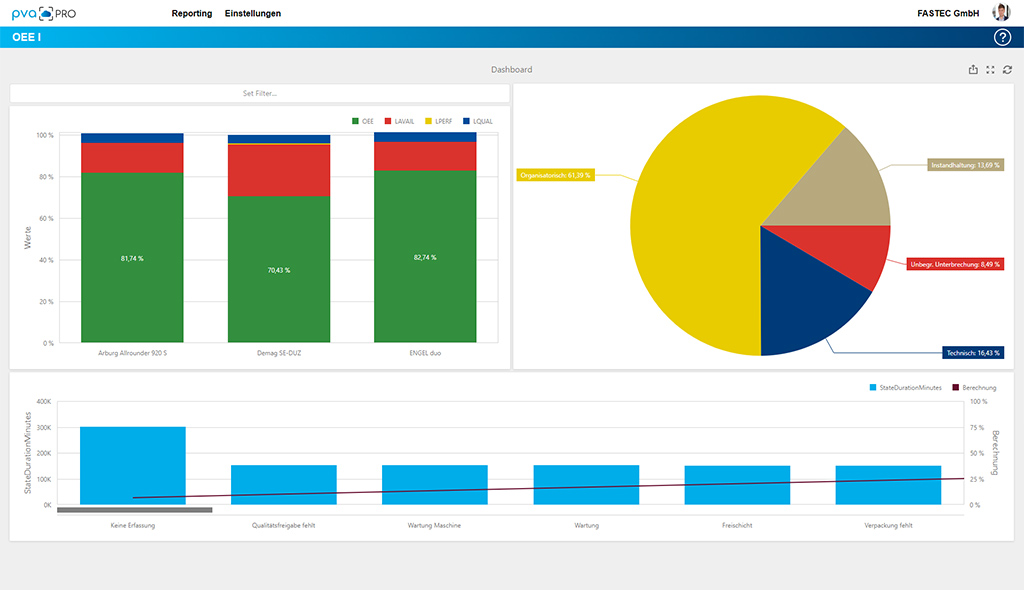

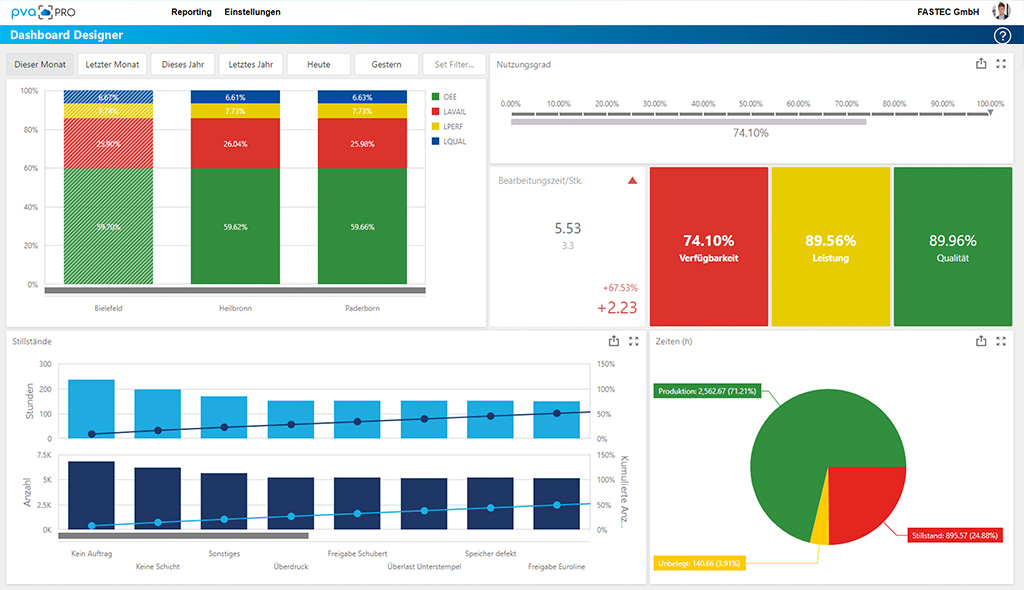

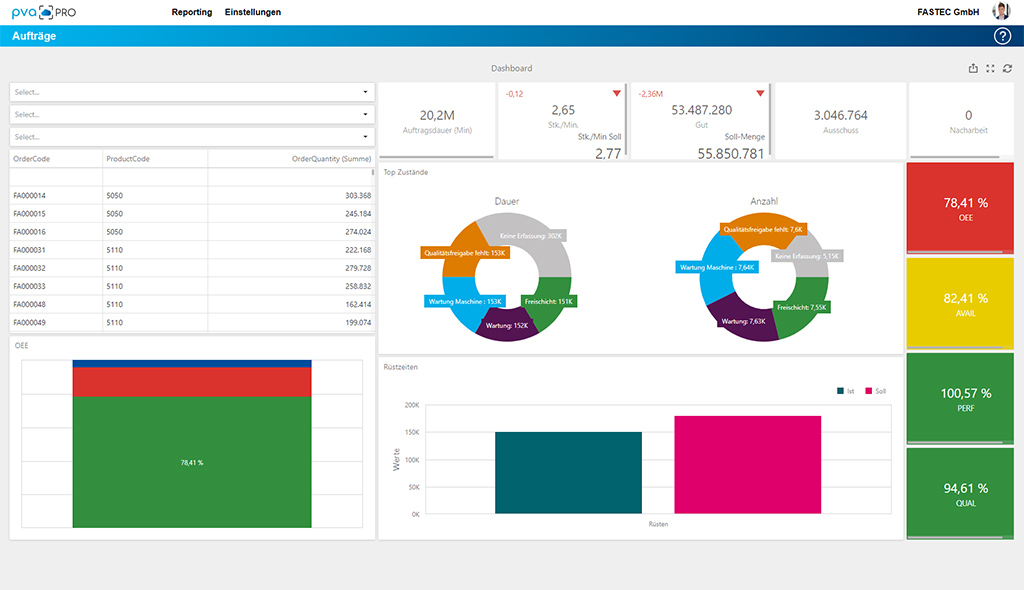

As the software foundation for data acquisition, we use the long-established MES FASTEC 4 PRO.. Data analysis is carried out in the cloud system pvaPRO. The result: a reliable, straightforward plug & play solution that you can implement quickly and easily.

Plant Management

Data Acquisition

Machine Connection

Operation

Dashboards

Key Figures

Location Management

Data Acquisition

Machine Connection

Operation

Dashboards

Key Performance Indicator (KPI)

Analyze Production Data: in Intuitive Dashboards

Our Solutions – Your Success

As a solution partner for the factories of the future, we offer high-performance products combined with partnership-based cooperation. Over 400 companies worldwide already trust us and achieve impressive results with our solutions.

Optimization Measures

Based on the data collected, the company has implemented over 130 optimization measures.

Dr. Willmar Schwabe GmbH & Co. KG

Months until ROI

By analyzing the data and implementing improvements, the return on investment (ROI) was achieved within 12 months.

Bausch Health Companies Inc.

OEE Increase

Normbau achieved an increase in Overall Equipment Effectiveness (OEE) of almost 30 percent with our solutions.

NORMBAU GmbH

"FASTEC's OEE system provides the necessary transparency to identify, report and sustainably eliminate recurring sources of disruption."

"All these advantages have almost alone led us to improve the OEE on this line by 10% with the right team and have convinced us to equip further production lines with the easyOEE system."

"In our search for a suitable MES, in which we looked at the solutions of a number of providers, we chose FASTEC again quite quickly; on one hand, because we already had the best experience with easyOEE – which we are, as a matter of fact, still using – and on the other hand, because we are able to expand the modularity of the system at any time and thus, adjust our MES easily to new requirements."

"Thanks to FASTEC, we identified idle times in production that we were previously unaware of. The conversion of this process was the main driver for the OEE increase in this plant."

"With FASTEC, we got the usability and data quality we were looking for. The individual generation of overviews and dashboards as well as the general clarity convinced us."

6 Steps to Your "turnkey" smartOEE

You will receive your preconfigured system and the corresponding hardware within a short period of time. Implementation is simple and operation is intuitive. Support is then available to answer any questions you may have.

Preparation

Configuration

Shipping

Installation

Integration

Activation

Preparation

Configuration

Shipping

Installation

Integration

Activation

Everything From a Single Source: Seamless Interaction of Software and Hardware

The edge components are provided by our FASTedge product family. You benefit from the option of renting our hardware flexibly and receiving a replacement device within 48 hours.

Hybrid Architecture

EdgeBox

Terminal

Pricing

Starter Package:

3 months of use

only pay for 2 months

€3,875

Rental:

Starting from month 4

monthly

€650

Rollout

Each additional machine

monthly

€180

FAQ

Production data is digitally collected and can be evaluated directly in the cloud. By automatically calculating the Overall Equipment Effectiveness (OEE), you can derive optimization measures and thereby increase the productivity of your production.

State-of-the-art Microsoft Azure technologies ensure secure encryption of your data in the cloud. The FASTEC 4 PRO MES takes care of data acquisition and machine connection. The connection between FASTEC 4 PRO and pvaPRO is secured via HTTPS; authentication also takes place between the two. The data is stored on servers in Western Europe.

In addition to machine and operating data with a focus on Overall Equipment Effectiveness (OEE), you also record machine up and downtimes precisely. The automatic and/or manual recording of e.g. quantities, scrap quantities and the assignment of states, e.g. production, downtime, malfunction, takes place.

Yes, the first month is free of charge. You can test the system easily and without any obligations. After configuration, simple installation and activation, you can start using it right away (plug & play). Depending on your payment plan, you can terminate the rental on a monthly, annual or custom basis.

We provide you with the entire IT infrastructure you need to get started successfully. All we expect from you is a functioning network and internet connection.

Yes, you can optionally book a preparatory workshop, a potential analysis, support with the machine connection or an OPEX consultation. There are also various care packages available for both pvaPRO and the FASTedge hardware. Here you have the choice between: Basic Care, Professional Care, Premium Care.

You can integrate any number of machines into the system and continuously add further functions. As the modular MES FASTEC 4 PRO is used for data acquisition, you can add all available functions at any time. You can find the entire range on our website.